Topic of your interest

Examination of bookbinding products

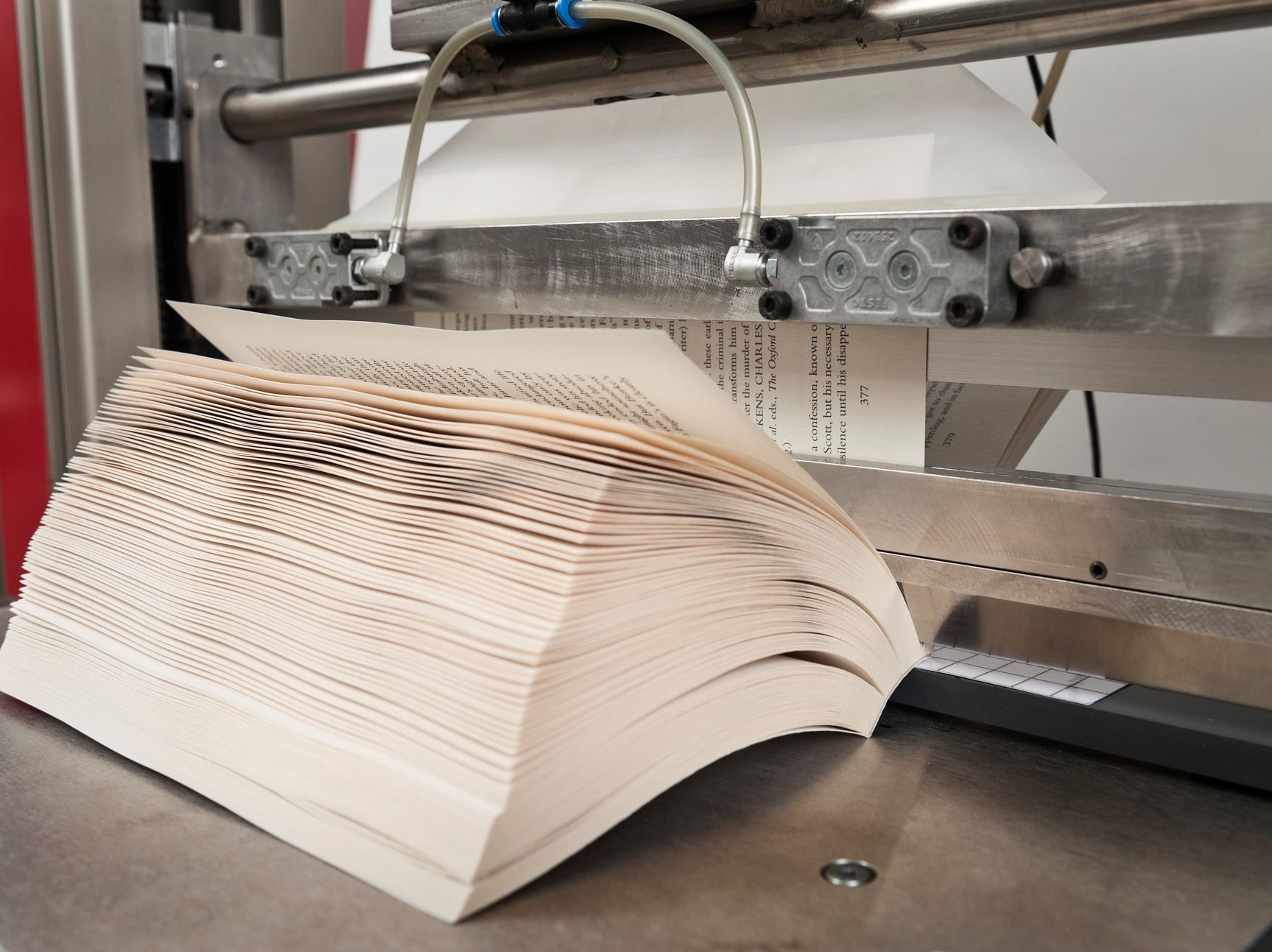

Are you a purchasing agent or manufacturer of print products and would like to have a bookbinding product checked with regard to one or more quality criteria? For books and brochures there are many quality criteria. We are not only familiar with the associated standards and guidelines, we have also actively participated in many of them.

Your benefit

A complaint caused by insufficient quality is often associated with high costs, as the problem is usually first noticed by the end customer. With a manageable amount of effort it is possible to test materials for their suitability in advance of production. Furthermore, in the case of a complaint it can be determined whether the cause has a material or production-related background.

A selection of our test methods:

Sheet tear strength (Pulltest)

Adhesive application, e.g. layer thickness, adhesive inflows

Dimensional accuracy, e.g. deviations in cutting, folding, typesetting mirror

flatness, e.g. waviness in the book block, book cover flatness

Book opening behaviour (layflat vs. clamping)

Foil or coating adhesion

Chemical analyses, e.g. mineral oil migration, through-greasing of hot melts

Climate tests, e.g. cold breakresistance and heat resistance

Your contact

Do you need our help with bookbinding questions or examinations? Contact me without obligation to discuss everything else!

What you need to do

You have had a perfect bound brochure produced as a repeat order and are not satisfied with the binding quality compared to the first production? Would you like to have it checked whether there are measurable differences in quality between the two productions?

Our procedure

We recommend that you carry out pull tests to determine the sheet tear resistance and ask you to send us at least five samples of both productions. Upon receipt of the sample books, a visual inspection is generally carried out to detect any abnormalities at an early stage. Once the samples have been conditioned, the pull test is carried out on a calibrated tester to determine the sheet tear-out resistance according to ISO 19594. In this test, a sheet is torn out of the sample book with a force acting perpendicular to the waistband and the maximum force is determined. This is divided by the format height and results in the sheet tear-out strength. The test result is evaluated according to the quality rankings of ISO 19594.

Our offer

Execution of a pull test (always sample books from 2 productions, 1 test per sample book)

€ 8.33 (Fogra member) | € 11.90 (normal)

I would be pleased to provide you a non-binding offer for the testing of bookbinding products: